I. PRINCIPLE OF OPERATION AND CLASSIFICATION OF INTERNAL COMBUSTION ENGINES

1. Principle of Operation

An Internal Combustion Engine (ICE) is a type of engine in which fuel is burned directly inside the combustion chamber. The heat generated from combustion produces high pressure that pushes the piston in a reciprocating motion. This linear motion is transmitted through the connecting rod to the crankshaft, converting it into rotary motion to drive machines or vehicles.

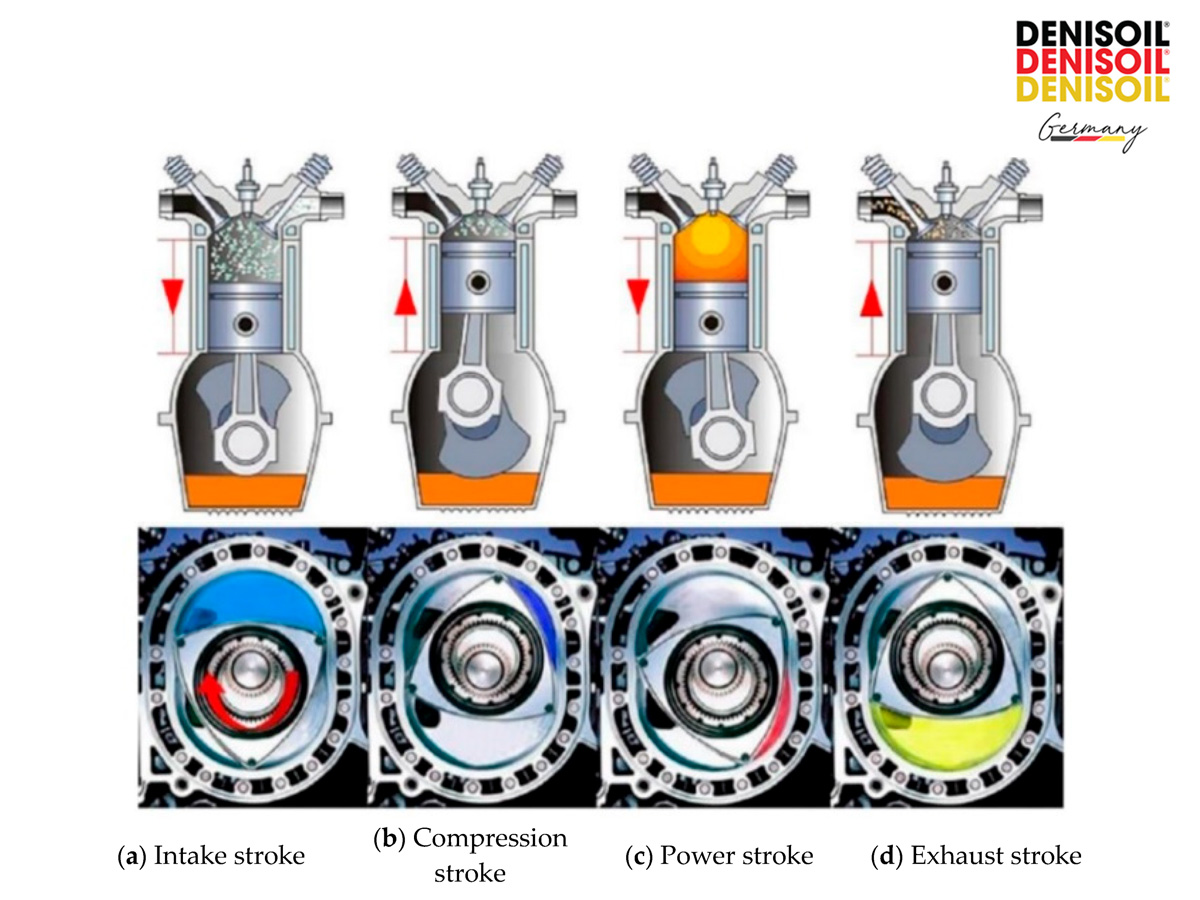

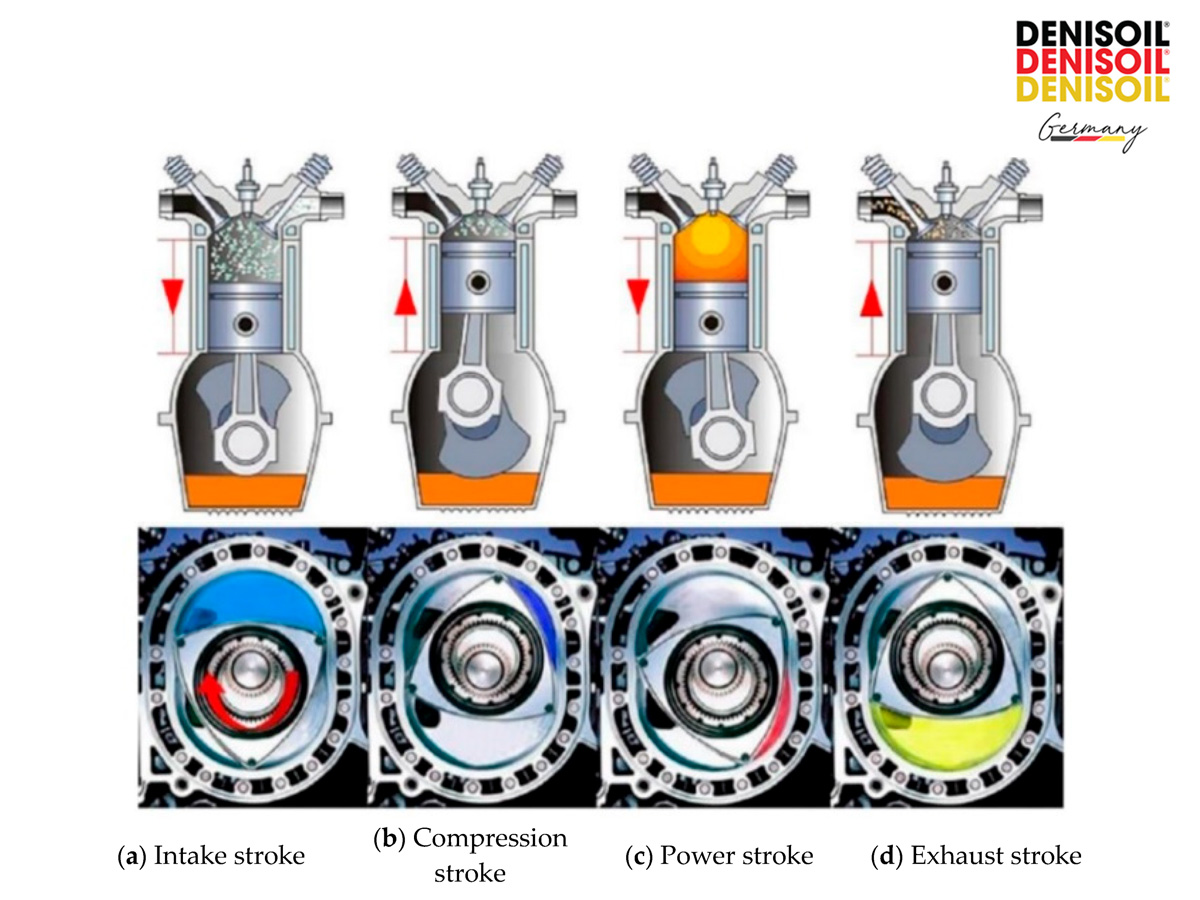

The Four-Stroke Cycle:

- Intake stroke: The piston moves downward, and the intake valve opens to draw in the air-fuel mixture (gasoline engine) or air (diesel engine).

- Compression stroke: The piston moves upward with both valves closed, compressing the mixture.

- Power stroke:

- In gasoline engines, the spark plug ignites the compressed mixture.

- In diesel engines, fuel is injected into the compressed hot air and self-ignites.

The combustion produces high pressure, pushing the piston down.

- Exhaust stroke: The piston moves up again, and the exhaust valve opens to expel burnt gases.

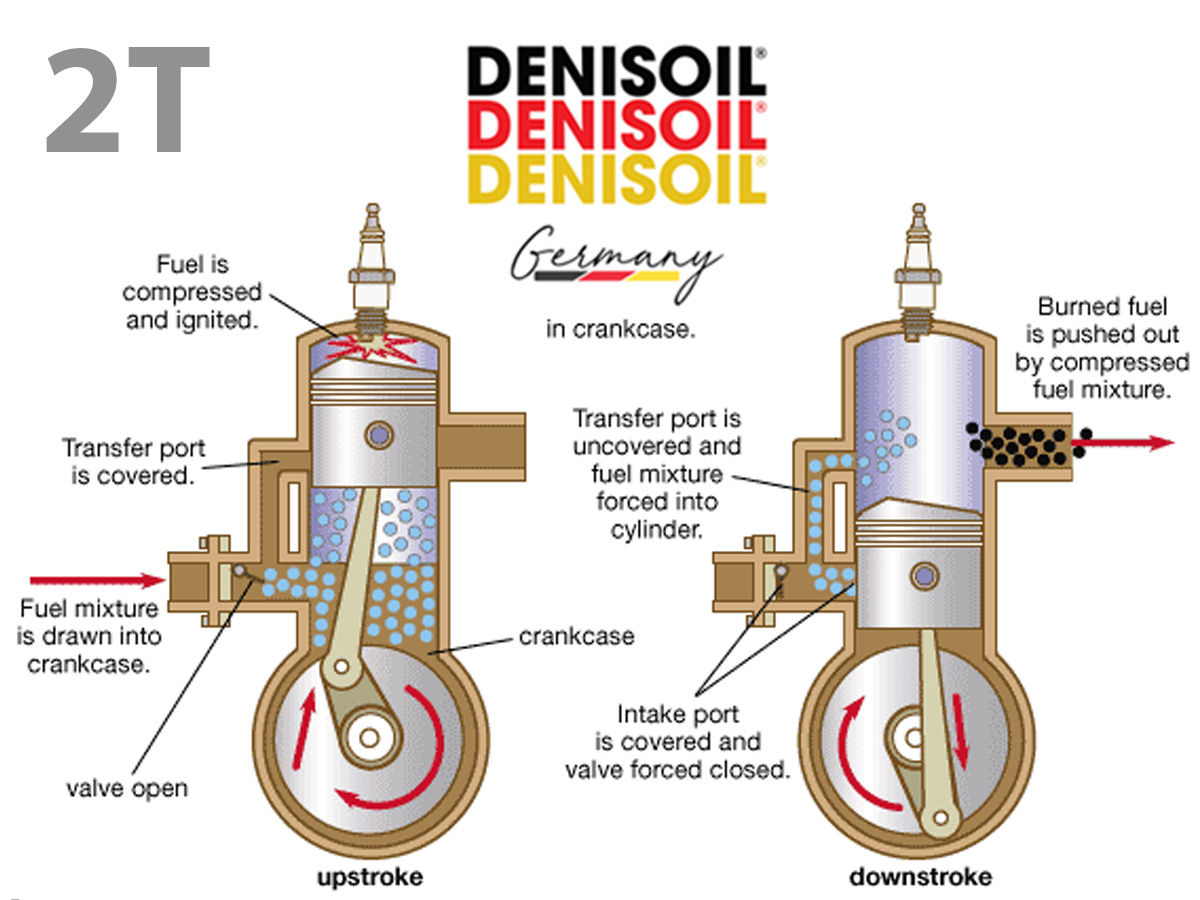

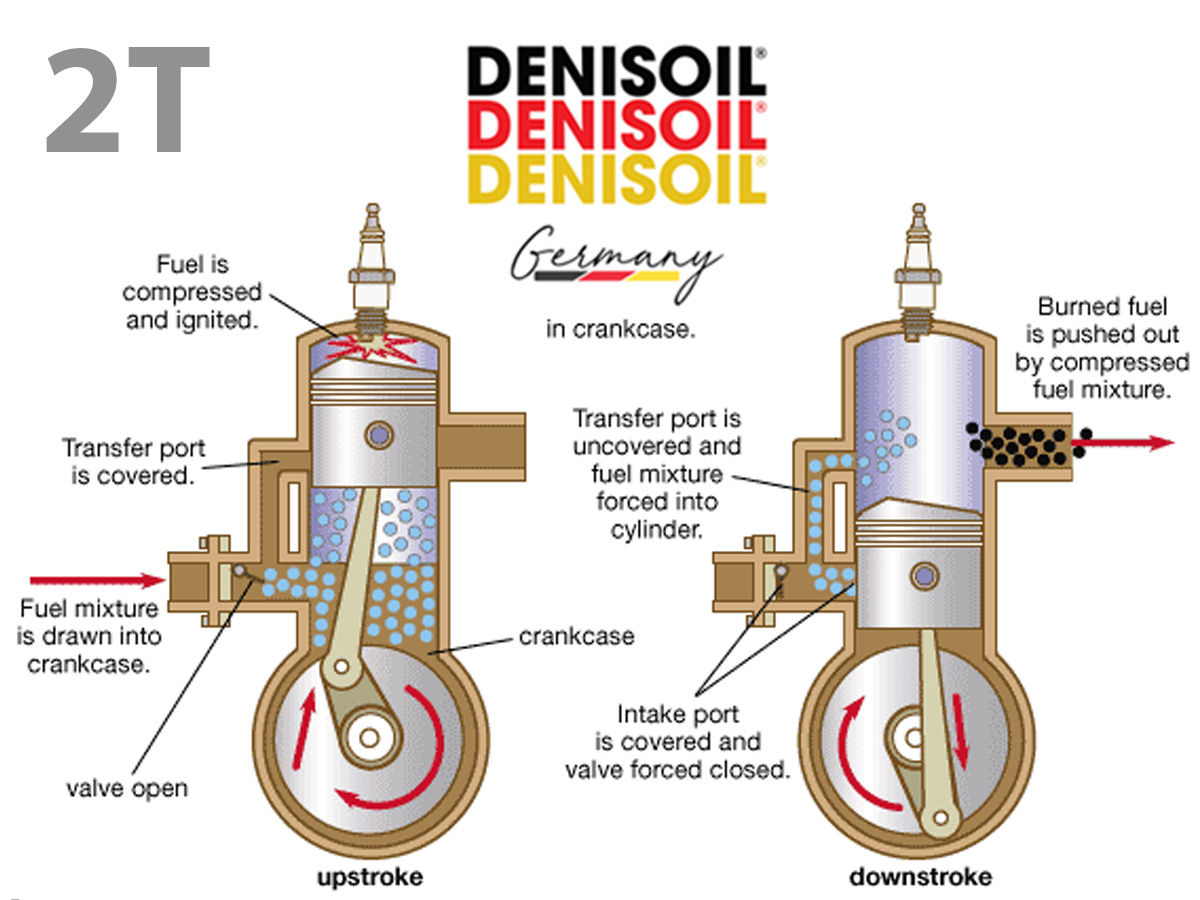

Two-stroke engines combine intake–compression and power–exhaust strokes into one cycle per crankshaft revolution, making them more compact and powerful for their size but less fuel-efficient and more polluting.

2. Classification of Internal Combustion Engines

a) By fuel type:

- Gasoline Engine (Spark Ignition – SI)

- Diesel Engine (Compression Ignition – CI)

- Gas-Fueled Engine: CNG (Compressed Natural Gas), LPG (Liquefied Petroleum Gas)

b) By operating cycle:

- Four-stroke engine

- Two-stroke engine

c) By application:

- Automotive engines (cars, motorcycles)

- Industrial engines (generators, construction machinery)

- Marine engines (ships, boats)

II. ENVIRONMENTAL REQUIREMENTS FOR INTERNAL COMBUSTION ENGINES

1. Reduction of Harmful Emissions:

- CO (Carbon Monoxide)

- NOx (Nitrogen Oxides)

- HC (Unburned Hydrocarbons)

- PM (Particulate Matter)

2. Compliance with Emission Standards:

- Euro 4–6 (Europe)

- EPA Tier levels (United States)

- TCVN (Vietnamese national standards)

3. Clean Technology Integration:

- EGR (Exhaust Gas Recirculation): Reduces NOx by recirculating part of the exhaust gas.

- Three-Way Catalytic Converter (TWC): Converts CO, HC, and NOx into CO₂, H₂O, and N₂.

- DPF (Diesel Particulate Filter): Captures fine particulates from diesel exhaust.

- SCR (Selective Catalytic Reduction): Uses urea (AdBlue) to convert NOx into nitrogen and water.

4. Use of Environmentally Friendly Lubricants:

- Low SAPS (Sulfated Ash, Phosphorus, Sulfur): Protects after-treatment devices (DPF, TWC).

- Compliant with standards such as API CK-4, FA-4 (USA), ACEA C1–C5 (Europe).

Tiếng Việt

Tiếng Việt

Chinese

Chinese

English

English