When machinery in factories encounters malfunctions or there's a need to understand “hydraulic oil,” lack of knowledge can lead to choosing the wrong product, reducing performance or damaging the system. This article not only provides an overview of hydraulic oil but also dives into technical details for factory technicians and experts.

1. What is Hydraulic Oil?

Hydraulic oil is a fluid used to transmit pressure and energy within a hydraulic system via pumps, valves, cylinders, and hydraulic motors. Besides its primary function of power transmission, hydraulic oil also:

- Lubricates moving parts to reduce wear.

- Seals gaps between components.

- Dissipates heat generated by compression and friction.

- Removes contaminants, prevents emulsification, and suppresses foam.

Key technical requirements:

- High oxidation stability.

- Anti-wear (AW) performance.

- Fast water separation.

- Compatibility with sealing materials (NBR, FKM, PTFE, PU, etc.).

- High viscosity index (VI ≥ 95 for standard, VI ≥ 130 for HV).

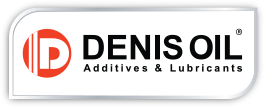

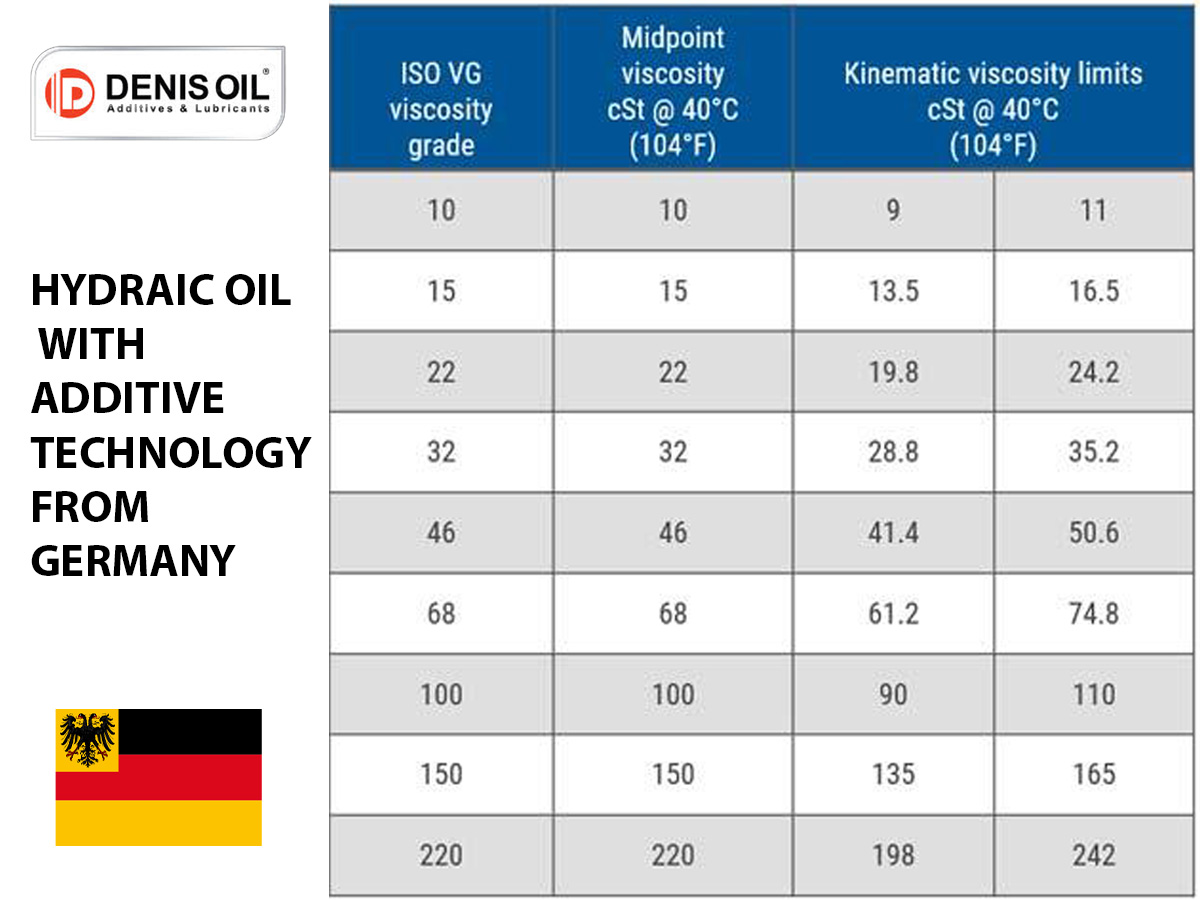

2. Meaning of Viscosity Grades 32, 46, 68

ISO VG grades are defined by kinematic viscosity at 40°C (unit: cSt):

|

Grade

|

Viscosity @40°C

|

Typical Application

|

Ambient Temp

|

|

VG 32

|

~32 cSt

|

High-speed equipment, low-temp

|

< 25°C

|

|

VG 46

|

~46 cSt

|

Presses, standard industrial use

|

25–35°C

|

|

VG 68

|

~68 cSt

|

Heavy-duty systems, high temp

|

> 35°C

|

Technical Note:

Always choose viscosity grade based on ambient temperature range, not perception.

If the hydraulic system has a cooler or heater, viscosity must be adjusted accordingly.

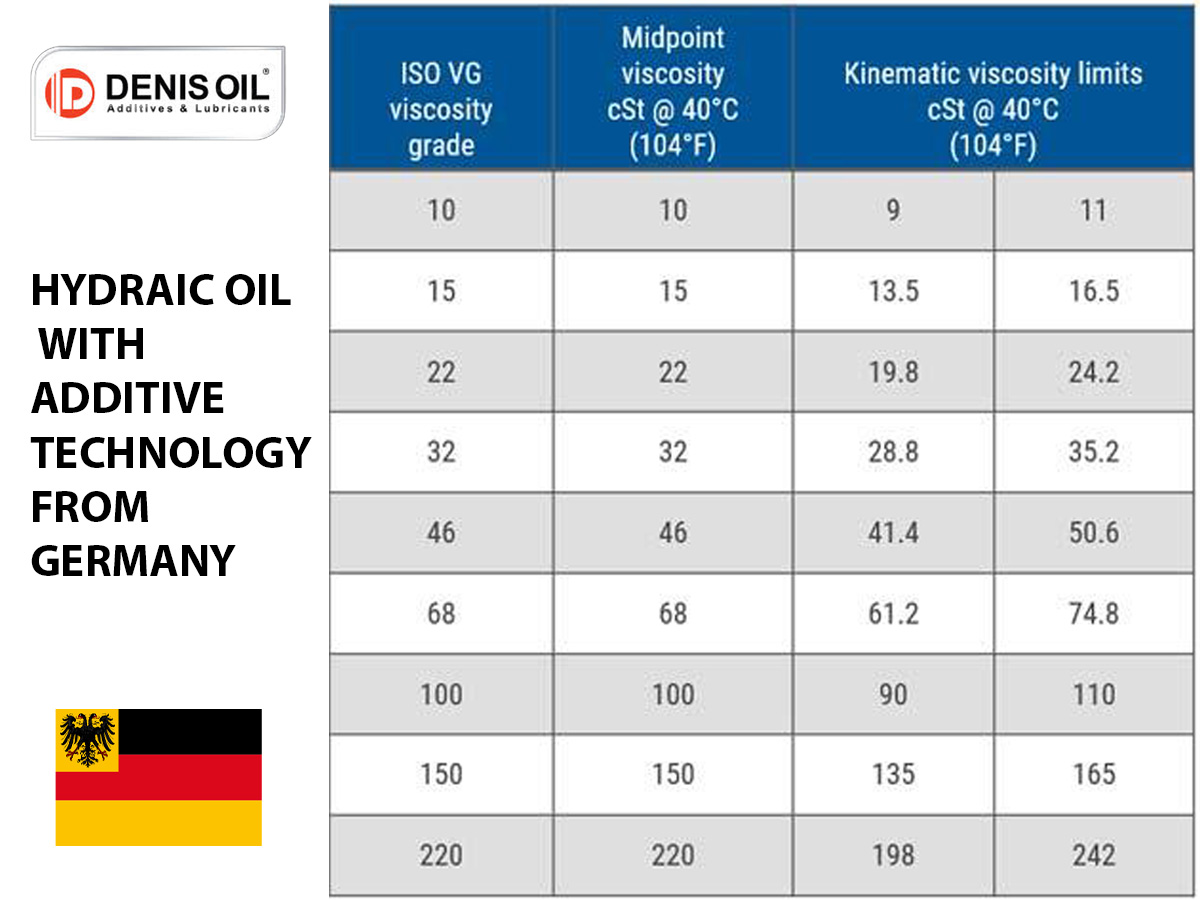

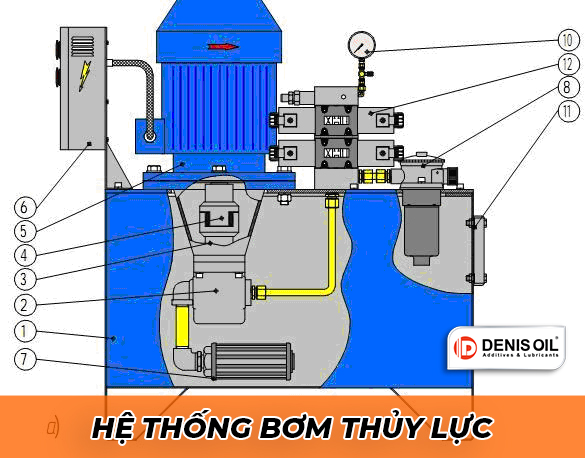

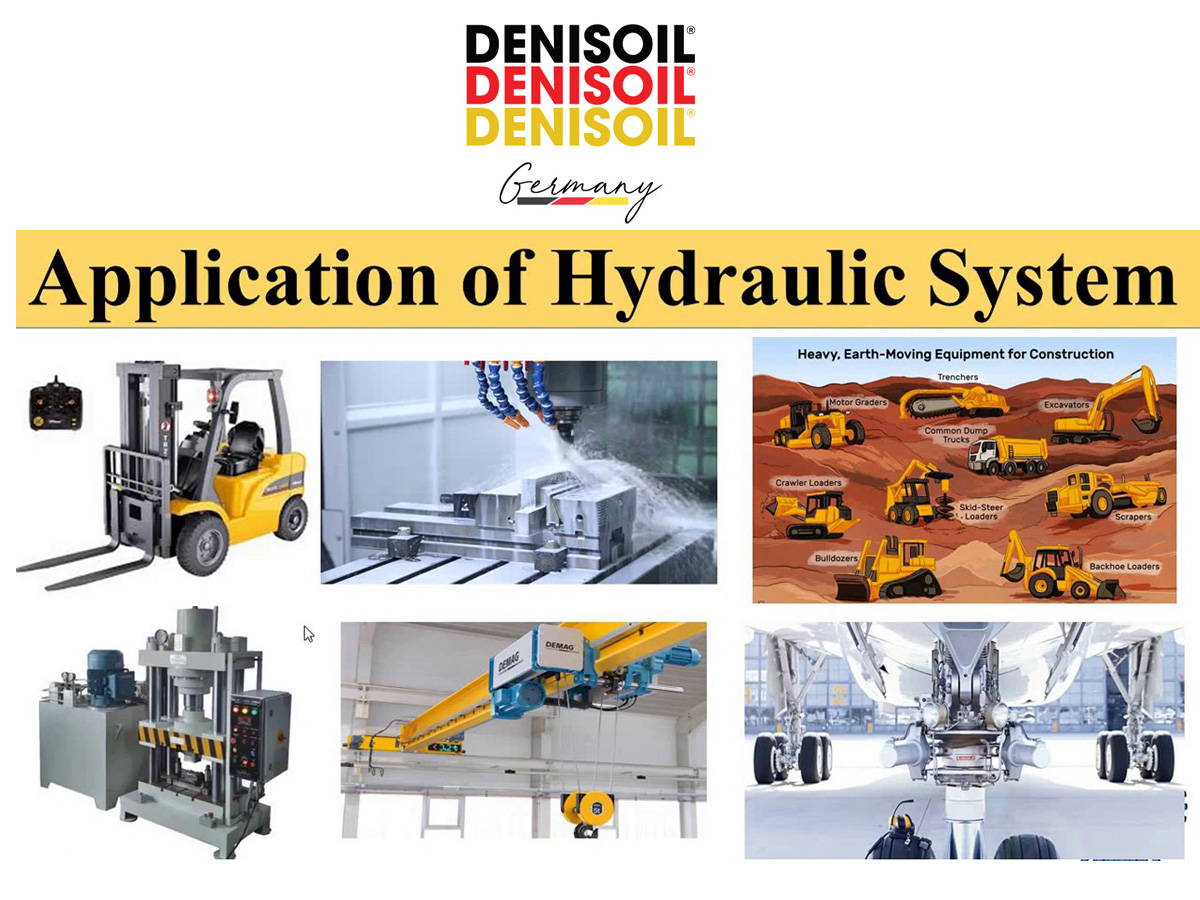

3. Applications and Hydraulic System Structure

Hydraulic oil is used in systems such as:

- Presses, stamping machines, CNC machines, plastic extruders.

- Lifting systems, construction machinery, excavators, cranes.

- Metal processing equipment, steel rollers, coil machines.

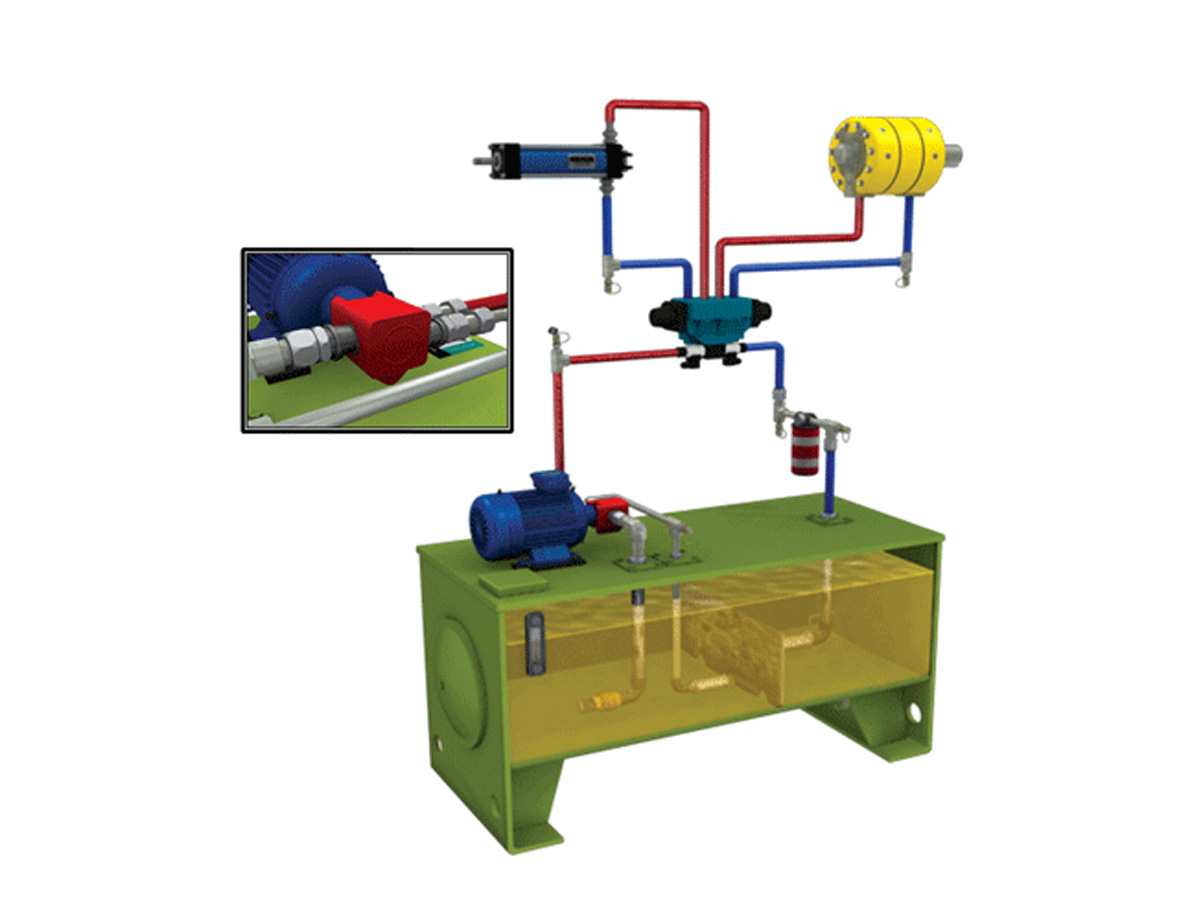

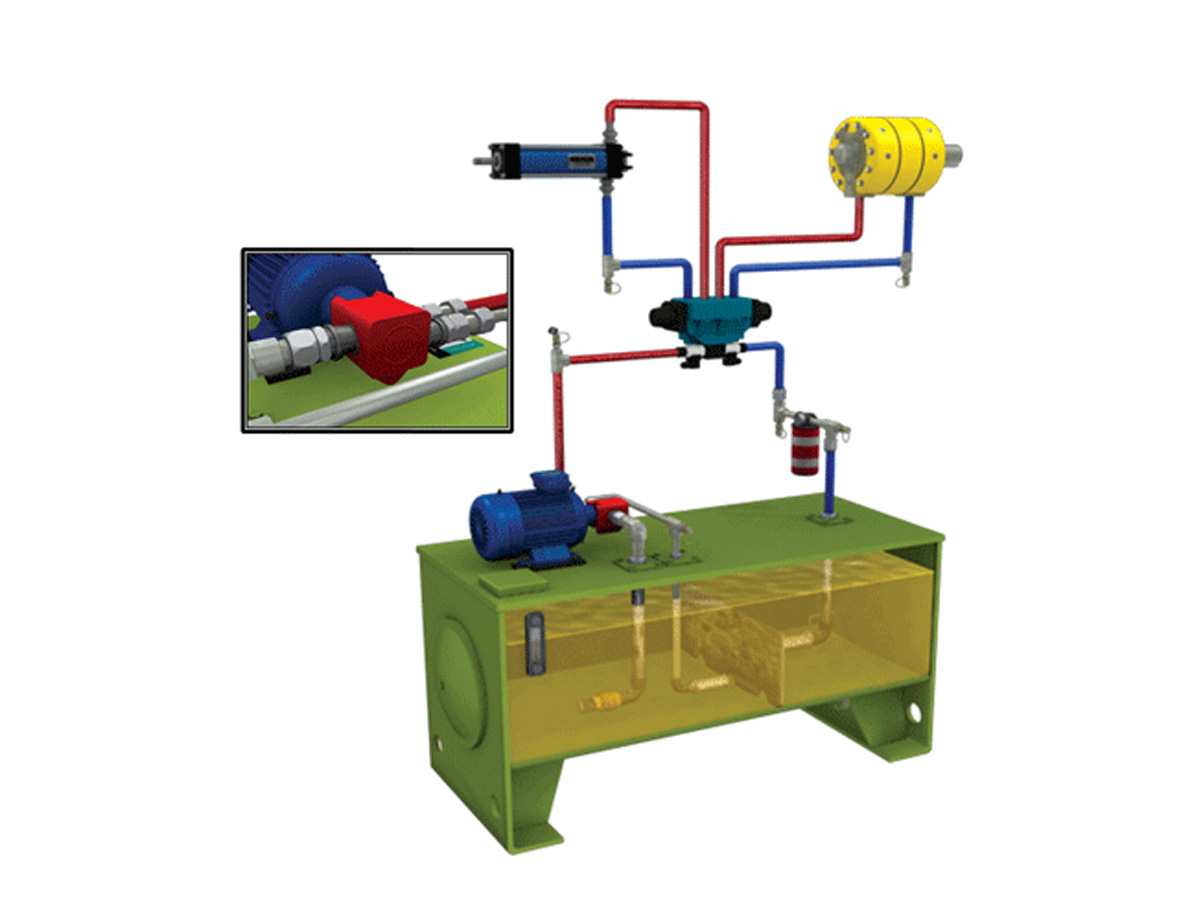

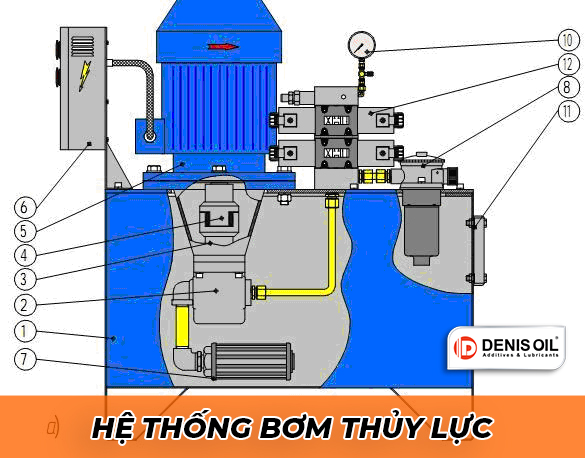

Typical system components:

- Hydraulic pumps (vane, piston, gear types).

- Control valves (pressure, flow, directional).

- Piping, accumulators, oil filters, coolers.

- Cylinders, hydraulic motors.

4. Detailed Functions of Hydraulic Oil

- Energy transmission – Transfers force via nearly incompressible fluid.

- Lubrication – Reduces metal-to-metal friction.

- Sealing – Prevents air ingress and internal leakage.

- Cooling – Carries away heat from friction zones.

- Anti-wear protection – AW and EP additives protect surfaces.

- Detergency – Dispersant additives suspend sludge.

- Demulsifying & Anti-foam – Prevents cavitation and water-oil emulsions.

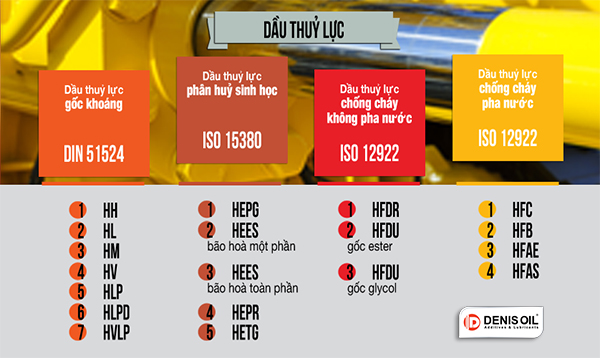

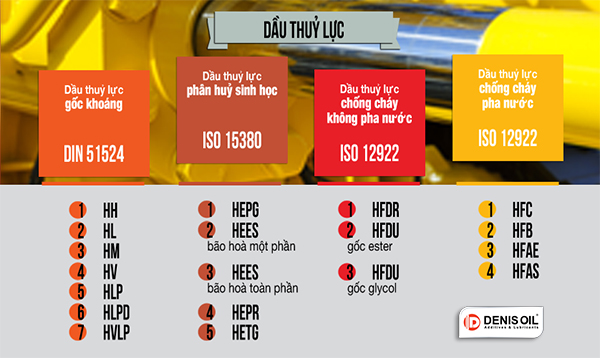

5. Types of Hydraulic Oil

By base oil:

- Mineral-based – Most common.

- Synthetic – High performance and thermal stability.

- Biodegradable – Environmentally friendly.

By fire resistance:

- HFAE, HFAS, HFB, HFC, HFDR, HFDU – For high-temperature or flammable environments.

By DIN/ISO classification:

|

Code

|

Description

|

|

HH

|

Refined mineral oil without additives

|

|

HL

|

HH + anti-oxidation and rust inhibitors

|

|

HM

|

HL + anti-wear additives

|

|

HV

|

HM + improved viscosity index

|

|

HLP

|

Equivalent to HM under DIN

|

|

HLPD

|

HLP + detergents and anti-sludge additives

|

6. Criteria for Choosing the Right Oil

Evaluate based on 5 key factors:

- Viscosity

- Heat/fire resistance

- OEM documentation or equipment recommendations

- Seal materials used (PTFE, Viton, NBR, etc.)

- Operating environment (dust, water, temperature, vibration)

Expert advice:

- Always follow equipment manufacturer's recommendations.

- Use HV oil for wide temperature range operations.

- Use HLPD oil in dusty or high-moisture environments.

7. Dangers of Incorrect Viscosity Selection

High viscosity:

- Increased friction → heat → energy loss.

- Reduced control sensitivity → actuation errors.

Low viscosity:

- Higher internal leakage → lower working pressure.

- Weak oil film → more wear → shorter equipment life.

- Causes cavitation in pumps, cylinders.

8. Maintenance & Oil Condition Checks

Inspection frequency:

Every 500–1000 hours or every 3 months.

Tests to perform:

- Viscosity at 40°C

- Water content (ASTM D6304)

- Wear metal content (spectrometric analysis)

- Oxidation index (TAN)

Signs oil needs replacing:

- Color change, burnt odor.

- Foaming or water layer at tank bottom.

- Noticeable drop in machine performance.

9. Where to Buy Hydraulic Oil?

Choose suppliers that:

- Provide valid COA, CO, CQ, and MSDS.

- Are authorized distributors of reputable brands.

- Have expert teams to advise on correct type and viscosity.

10. Summary for Technicians & Experts

Choosing the correct hydraulic oil ensures:

- Precise, stable system performance.

- Longer life for pumps, valves, cylinders.

- Lower energy use and maintenance costs.

Always evaluate hydraulic oil based on technical standards, not just price.

Contact GODIVA IMPORT-EXPORT CO., LTD for expert technical consultation and genuine, certified hydraulic oils!

Tiếng Việt

Tiếng Việt

Chinese

Chinese

English

English